Content

- 1

- 2 Introduction

- 3 What is a Printed Circuit Board (PCB)?

- 4 The Evolution of Kitchen Appliances with PCBs

- 5 How PCBs Power Common Kitchen Appliances

- 6 1. Microwave Ovens

- 7 2. Refrigerators

- 8 3. Dishwashers

- 9 4. Ovens and Cooktops

- 10 5. Coffee Machines and Blenders

- 11 Key Design Considerations for Kitchen PCBs

- 12 Heat Resistance

- 13 Moisture and Chemical Exposure

- 14 Electrical Safety

- 15 Compactness and Integration

- 16 Electromagnetic Interference (EMI)

- 17 The Future of PCBs in Kitchen Technology

- 18 IoT and Connectivity

- 19 Advanced Sensors

- 20 Energy Efficiency

- 21 Flexible and Wearable PCBs

- 22 Conclusion

Introduction

In today’s technologically driven world, our kitchens are becoming smarter, more efficient, and increasingly automated. From refrigerators that monitor your groceries to ovens that cook food to perfection with minimal effort, the kitchen of the 21st century is a marvel of innovation. At the heart of this transformation lies a small but powerful component known as the Printed Circuit Board, or PCB

Though often invisible to the end-user, PCBs are the foundation upon which modern kitchen appliances are built. They enable everything from simple timing functions to complex sensor-driven automation and wireless connectivity. This article delves into how PCBs contribute to kitchen technology, their design challenges, and what the future holds for PCB use in kitchens.

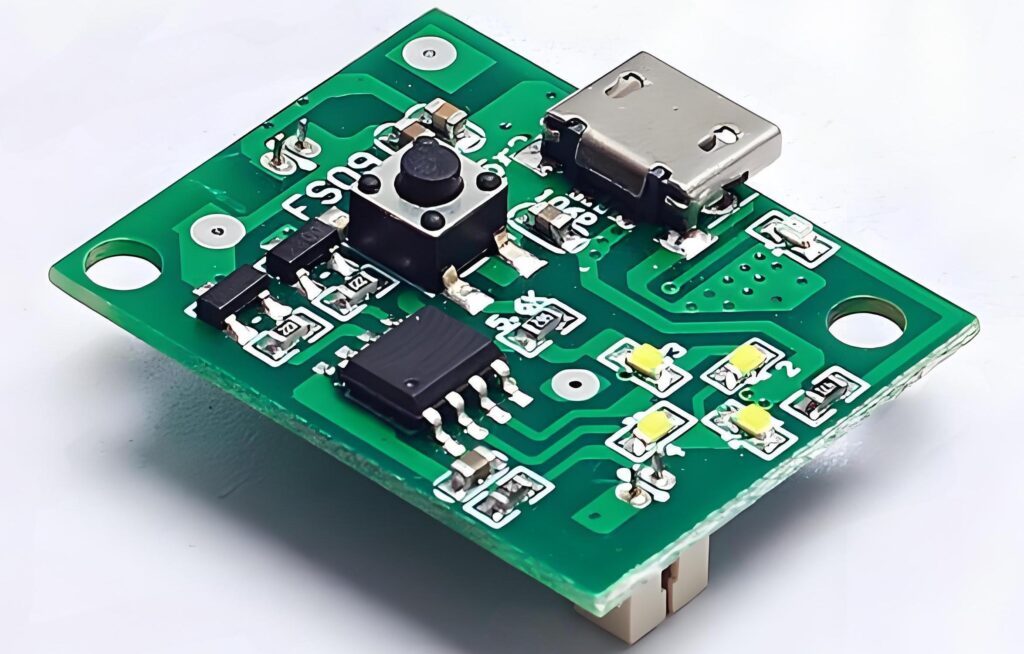

What is a Printed Circuit Board (PCB)?

A Printed Circuit Board is a flat, typically green board composed of insulating material, such as fiberglass, onto which conductive copper pathways are etched or printed. These pathways connect various electronic components like microcontrollers, sensors, resistors, capacitors, and integrated circuits that are soldered onto the board.

PCBs provide the electrical foundation for all modern electronics, allowing signals and power to be routed efficiently and reliably. They range in complexity from simple single-layer boards to complex multi-layer boards with thousands of connections, depending on the application.

The Evolution of Kitchen Appliances with PCBs

Historically, kitchen appliances were primarily mechanical devices with simple electrical components. Traditional ovens, stoves, and refrigerators relied on manual controls, timers, and mechanical switches. As technology progressed, manufacturers began incorporating electronic components for better control and efficiency.

The introduction of PCBs allowed for the integration of digital control systems, sensors, and programmable logic, paving the way for smarter kitchen devices. Today’s kitchen appliances boast touchscreens, sensor-based cooking programs, energy-efficient operation, and even internet connectivity—all made possible by PCBs.

How PCBs Power Common Kitchen Appliances

1. Microwave Ovens

Modern microwaves depend heavily on PCBs to regulate power output, control cooking time, and manage sensor inputs. Inverter technology, which allows microwaves to cook food more evenly, is controlled by specialized PCB circuitry. The user interface, including buttons and digital displays, also relies on PCBs for responsiveness and reliability.

2. Refrigerators

PCBs in refrigerators control compressor cycles, temperature regulation, humidity control, and defrost functions. Advanced smart refrigerators use PCBs to handle internal cameras, touchscreen displays, Wi-Fi connectivity, and integration with smart home systems. This allows users to monitor their fridge remotely, receive alerts, and even order groceries.

3. Dishwashers

Dishwasher PCBs manage complex wash cycles, control water temperature and pressure, monitor detergent dispensing, and regulate drying modes. Connectivity features enabled by PCBs allow remote monitoring, status alerts, and maintenance notifications.

4. Ovens and Cooktops

Electronic ovens use PCBs for precise temperature control, cooking timers, and safety features like automatic shutoff. Induction cooktops utilize PCBs to generate and regulate electromagnetic fields that heat cookware efficiently without heating the cooktop surface.

5. Coffee Machines and Blenders

Programmable coffee makers and blenders use PCBs to provide multiple settings, variable speeds, and auto-cleaning cycles. Some models offer connectivity to smartphone apps for remote control and personalized brewing or blending preferences.

Key Design Considerations for Kitchen PCBs

Designing PCBs for kitchen appliances requires overcoming specific challenges posed by the kitchen environment:

Heat Resistance

Kitchens involve high-temperature appliances like ovens, stoves, and toasters. PCB materials and components must withstand these temperatures without degrading or losing function. Thermal management techniques, such as heat sinks and heat-resistant substrates, are often used.

Moisture and Chemical Exposure

Kitchens are humid and prone to spills from water, oils, and cleaning chemicals. PCBs must be protected with conformal coatings or encapsulation to prevent corrosion and electrical shorts.

Electrical Safety

Kitchen appliances operate at relatively high voltages. PCB traces must be designed to handle current loads safely, with appropriate spacing and insulation to prevent electrical hazards.

Compactness and Integration

Modern appliances require more functionality in smaller spaces. Multi-layer PCB designs allow greater component density and more complex functionality while maintaining a compact footprint.

Electromagnetic Interference (EMI)

Kitchens are filled with electronic devices. Proper PCB layout and shielding are critical to minimize interference and comply with safety and electromagnetic compatibility standards.

The Future of PCBs in Kitchen Technology

The integration of the Internet of Things (IoT) and artificial intelligence (AI) into kitchen appliances is rapidly increasing, and PCBs are evolving to meet these demands.

IoT and Connectivity

PCBs with embedded Wi-Fi, Bluetooth, or Zigbee modules enable kitchen appliances to connect to smartphones and smart home systems. This allows remote control, status monitoring, and automation—turning kitchens into interactive spaces.

Advanced Sensors

Future PCBs will incorporate more sophisticated sensors for humidity, temperature, food quality, and freshness. These sensors will provide real-time feedback to users and optimize cooking and preservation processes.

Energy Efficiency

As sustainability becomes paramount, PCBs will play a vital role in managing power consumption intelligently, reducing waste and energy bills.

Flexible and Wearable PCBs

Emerging flexible PCB technologies may lead to innovative kitchen interfaces—such as smart countertops, flexible displays, or interactive utensils—blurring the lines between electronics and kitchenware.

Conclusion

Printed Circuit Boards are the unsung heroes of modern kitchen technology. They enable appliances to be smarter, safer, and more connected, transforming everyday cooking and food storage into seamless, efficient experiences. As technology advances, the role of PCB will only grow, driving innovation that makes kitchens more intuitive, energy-efficient, and integrated with our digital lives.

By understanding the importance of PCBs in kitchen appliances, consumers and designers alike can appreciate the complex engineering behind the conveniences we often take for granted. Whether it’s ensuring your coffee is brewed perfectly or your fridge monitors your groceries, PCBs quietly empower the heart of the modern kitchen.